Meeting Unique Needs

The chemical processing industry comes with a unique set of challenges, and AT&F is well prepared to handle them head-on. From meeting tight tolerances to upholding regulatory standards, we have what it takes to get the job done right.

Our Place or Yours

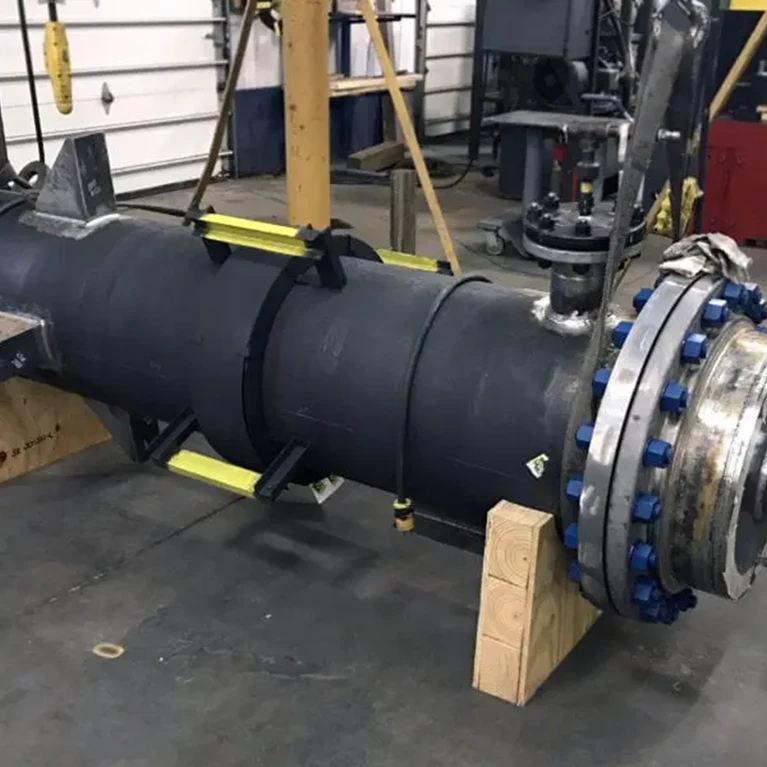

We can rebuild, repair or modify process equipment onsite at your facility, or in-house at AT&F. Our process equipment repair services include solutions for:

- Shell and tube heat exchangers

- Pressure vessels

- Tanks

- Columns and towers

- Piping systems

- Anodes and cathodes

- Heating coils

- Fans and Impellers

- General fabrications

Certified Chemical & Pharmaceutical Fabrication

We are an ASME Code shop and are certified to Section VIII Division 1 Code. We also comply with TEMA standards in our design and fabrication of heat exchangers. All of our welders are qualified in accordance with ASME Section IX and all inspectors are AWS Certified Welding Inspectors in accordance with QC1-96 and NDT certified in accordance with SNT-TC-1A.